Steelwrist presents the first model in its third generation of tiltrotators with the launch of XTR20

Story Highlights

- Steelwrist

- tiltrotator

- 3rd generation of tiltrotators

- Open-S

- OptiLube

- LockSense technology

Related Articles

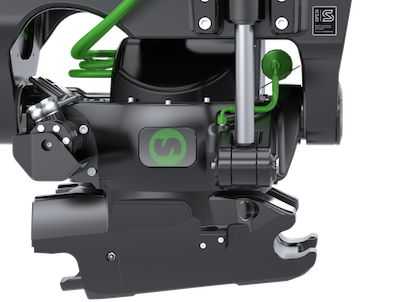

On March 13-14, 2024, Steelwrist hosted a launch event at Steelwrist Deutschland GmbH’s new facility in Hamburg, presenting the most innovative product launch in the company’s history. The XTR20 is the first in line of Steelwrist third-generation tiltrotators which is targeted towards 16-20 ton excavators and takes efficiency to the next level. Best-in-class tilt geometry, LockSense – a new patented safety solution for work tool locking and OptiLube – an onboard lubrication system, are just some of the technical developments of the third generation high-performance Steelwrist tiltrotators. The XTR20 is available with both S60 and SQ60 couplers and is designed to allow for an upgrade from S60 to SQ60, providing the customer with flexibility to adapt as the needs evolve.

Steel casted components and optimized tilt geometry

The new XTR20 has steel casted components including the upper coupler, gearbox, and quick coupler below the tiltrotator. Despite its compact build, reducing the overall height, the XTR20 maintains a 45-degree tilting angle.

Steelwrist’s superior tilt geometry has evolved even further on the XTR20 to ensure the smoothest operation for the operator. Designed with off center tilt cylinder brackets the tilt cylinders have become shorter, optimizing the tilt geometry. This leads to minimized cylinder spread throughout the tilt stroke, providing a fluid and high-torque movement.

Steelwrist’s superior tilt geometry has evolved even further on the XTR20 to ensure the smoothest operation for the operator. Designed with off center tilt cylinder brackets the tilt cylinders have become shorter, optimizing the tilt geometry. This leads to minimized cylinder spread throughout the tilt stroke, providing a fluid and high-torque movement.

Lubrication-free bearing and OptiLube – the tiltrotator onboard lubrication system

A new feature introduced on the XTR20 are lubrication-free, triple-sealed bearings in all the main joints. Triple-sealed means that bearings are sealed against dust or dirt penetration. Today operators may forget to grease the tiltrotator or do not grease enough. In some cases, the tiltrotator is connected to the excavator’s central lubrication system where too often a very fluid or low-quality grease is used. The idea behind OptiLube is to ensure the tiltrotator is greased in the right amount, at the right time, and with an optimized grease, all to increase the tiltrotator’s lifespan.

With the new OptiLube onboard lubrication system, maintaining the Steelwrist tiltrotator has never been easier. The OptiLube system takes care of lubrication automatically, ensuring consistent and optimal performance. The lubricant used is specially developed for Steelwrist tiltrotators and reduces friction and extends lifetime. OptiLube is integrated into the tiltrotator’s control system, allowing for continuous monitoring of lubrication performance and alerts the operator when it is time to replace the lubricant cartridge. This feature eliminates guesswork and routine checks, allowing the operator to focus on the work without interruptions.

A leap in safety with LockSense technology

Safety is paramount and with XTR20 Steelwrist takes a new leap in terms of safety solutions, preparing for the future with LockSense. Steelwrist was first to introduce the Front Pin Lock system already in 2012 and this time again takes the lead in the technology development with the new LockSense system.

The XTR20 features our patented LockSense technology – a state-of-the-art sensor system for secure work tool locking. The innovative LockSense solution has the necessary features to be aligned with upcoming safety regulations. The wireless solution eliminates the hassle of delicate cables in exposed positions with a battery life time of approximately five years.

Operators receive both visual and auditory confirmations, ensuring that every work tool change is secure and reliable. It is more than just safety; it is peace of mind, ensuring that every job site is as safe as it is efficient.

Modular design for upgrade to the Open-S compliant SQ

Modular design for upgrade to the Open-S compliant SQ

The new tiltrotators, as well as all other Steelwrist products, are available with interfaces following the symmetrical standard (S standard), which is the fastest growing standard internationally. Thanks to the modular design it is possible to upgrade the tiltrotator from S-type to SQ-type. Steelwrist SQ technology allows the operator to change between hydraulic powered work tools in only seconds – all without leaving the cab.

On the new XTR20 and the other third generation tiltrotators that are still to come, the upgrade from S to SQ is possible on both the upper coupler and the tiltrotator quick coupler without having to change the structural parts as was the case on the previous models. A simple change of components will allow for the upgrade from S to SQ. This is both less time consuming and more economical for the customer.

All Steelwrist SQ products follow the global Open-S industry standard for automatic quick couplers for excavators. The ambition with the global Open-S industry standard is to give machine operators and contractors the freedom to combine quick couplers, tiltrotators and work tools from different manufacturers that follow the standard.

Integration to machine control system to further enhance efficiency

Machine Control Systems (MCS) continuously increase in popularity all over the world as these solutions significantly enhance the productivity and accuracy of the excavator. Historically the case has often been that Machine Control System suppliers had to fit their own tilt sensors on tiltrotators to get enough granularity on the tilt position of the work tool, with the XTR20 this is not necessary anymore.

The XTR20 comes equipped with high-resolution tilt and rotation sensors as standard. This integration offers the customer precise control, feeding exact positioning data to the Machine Control System. Steelwrist already today has a number of integrations available to all the most prominent Machine Control System suppliers.

“The XTR20 represents a leap forward in performance and reliability and with features like LockSense, OptiLube, more tilt and rotation torque and easy upgradeability we show our continued commitment to improving excavator efficiency. I am extremely proud of what our team has accomplished and I look forward to seeing the new Steelwrist XTR20 tiltrotator improving job sites around the world”, says Stefan Stockhaus, Steelwrist CEO.