Jungheinrich’s PowerCube compact storage system for containers

Story Highlights

- Sistem de depozitare compact pentru containere

- PowerCube

- Jungheinrich

- LogiMAT 2022

- compact storage system for containers

- automated warehouse systems

- intralogistica

Related Articles

Jungheinrich presented PowerCube, an automated compact storage system for containers, at LogiMAT 2022, opening up a new dimension in warehouse efficiency. PowerCube impresses with its unique use of space, maximum flexibility, strong performance, and simple physical and digital integration into existing warehouses. This Jungheinrich innovation thus sets new standards in the field of automated warehouse systems.

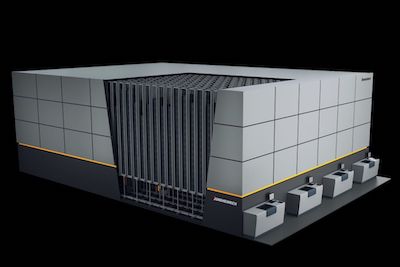

PowerCube is an automated compact storage system for containers that provides the particularly compact storage and order picking for small parts and general cargo. Containers are stacked on top of each other in vertical channels up to 12 m high within PowerCube’s modular racking system. This system height enables particularly space-efficient container storage in the smallest possible area. The containers are stored and retrieved by specially developed PowerCube shuttles that move automatically underneath the racking system. Thanks to this principle, PowerCube offers a decisive advantage over other compact storage systems, as the warehouse can be flexibly built upwards and can also be adapted to individual roof shapes.

PowerCube is an automated compact storage system for containers that provides the particularly compact storage and order picking for small parts and general cargo. Containers are stacked on top of each other in vertical channels up to 12 m high within PowerCube’s modular racking system. This system height enables particularly space-efficient container storage in the smallest possible area. The containers are stored and retrieved by specially developed PowerCube shuttles that move automatically underneath the racking system. Thanks to this principle, PowerCube offers a decisive advantage over other compact storage systems, as the warehouse can be flexibly built upwards and can also be adapted to individual roof shapes.

For Jungheinrich Chief Sales Officer Christian Erlach, PowerCube is the right answer to a multitude of current challenges in intralogistics: “Companies are under increasing time pressure or reaching the limits of their warehouse capacity. PowerCube is the perfect solution to significantly increase their warehouse efficiency under these conditions, thereby increasing their competitiveness. Thanks to its extremely high compactness and high performance, PowerCube changes space and time in the warehouse.” PowerCube is an ideal solution for customers planning to enter automation or for cross-industry use in e-commerce. “Whether as a stand-alone solution, an addition to wide-aisle warehouses, or the centerpiece of a complex automated system, PowerCube allows our customers to fully exploit the potential of their warehouse,” says Erlach.

Unique space utilization and high storage density

Thanks to the ultra-compact vertical arrangement of the containers, PowerCube makes ideal use of storage space and achieves a storage density four times higher than that of a conventional storage system. The system height of up to 12 m makes PowerCube the highest compact storage system for containers in its class. This creates space in the warehouse that can be used for goods range expansion or other purposes. The Jungheinrich PowerCube is also unique on the market in terms of flexibility. The automatic compact storage system for containers can be erected on normal industrial floors without extensive reworkings, such as over-milling or sanding, and can therefore be easily integrated into existing warehouses. Since the shuttles move underneath the containers, PowerCube can be easily extended upwards and adapted to different building structures. If necessary, it can also be connected to a customized conveyor system.

Powerful performance of the shuttles

Powerful performance of the shuttles

The newly developed PowerCube shuttles move at a maximum speed of 4 m/s and an acceleration of up to 2 m/s². They can simultaneously transport two containers with a load of 50 kg each, moving automatically in the plane below the PowerCube racking. Thanks to the scalable number of shuttles, the throughput of the PowerCube can be flexibly adjusted to meet increased demand or expansions in the product range. Thanks to their high-performance lithium-ion batteries, which are temporarily charged at the workstations during operation, the shuttles are ready for use 24 hours a day without downtime. This ensures high system throughput and makes the batteries a key reason for PowerCube’s strong performance. The lithium-ion batteries of the shuttles also impress with their low heat generation and the resulting low influence on the ambient temperature inside the container compact warehouse. Another plus point: as the shuttles can be removed from the PowerCube at floor level for maintenance work, no maintenance platform is required, unlike with competitor systems.

Smart IT integration for maximum performance

In PowerCube, Jungheinrich combines efficient processes and innovative hardware, with the help of state-of-the-art software technology. Advantages here include simple connection to the existing IT infrastructure on the customer side and the design of the software for maximum flexibility with regard to process and performance requirements. With PowerCube, Jungheinrich presents an integrated and holistic approach for the future of compact storage systems and delivers on its promise for a new dimension of efficiency in the warehouse.