Brokk has introduced next generation SmartConcept for demolition robot range

Related Articles

With the launch of four new models of Brokk demolition robots at Intermat 2018, the company has introduced SmartConcept, a package of technological features that offer significant improvements in power management, reliability, maintainability, and ergonomics to the latest generation of machines. Brokk is the world leader in the design, manufacture and sale of remote-controlled demolition machines, and SmartConcept, consisting of three areas of new technology – SmartPower, SmartDesign, and SmartRemote – represents a leap forward in performance and uptime across the board.

SmartPower

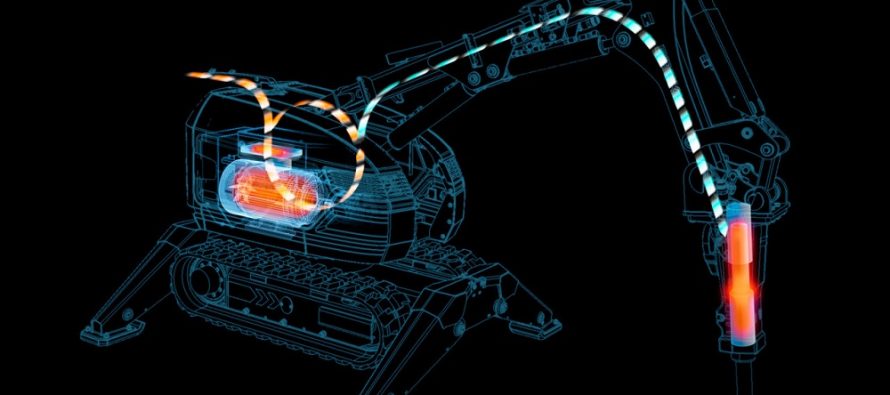

Now available on all but two of the model range, combines power management software with custom-designed hardware to maximize the hydraulic power output of a given motor size while boosting reliability. For example, the power generated in the B260, the company’s former flagship 3.5 ton model, was a constant 24kW. The next generation unit, the B280 with SmartPower, improved the output to just below 30kW. The newly launched B300, with a new electric motor and SmartPower, boasts 36kW of power, and means that the robot can accommodate a larger class of hammer on essentially the same size carrier. Better still, the integrated power management software automatically monitors the system and adjusts the motor speed to prevailing temperature conditions. This means that the machines can operate continuously even in the harshest, hottest environments.

In addition to the power management features, SmartPower includes completely redesigned electrical systems with 70% fewer cables and a reduction in connection points from 170 to about 50, and hardened components specifically designed to withstand the rigors of vibration and heat generated in demolition robots. Together, these improvements increase the overall life of the machine’s electrical and hydraulic components and guarantee greater uptime in real-world conditions.

SmartDesign

The new Brokk models include a number of deft design improvements put in place to extend the life of the machines and improve the operators’ day-to-day maintenance routines. All grease points are accessible from the outside, without removing any covers. LED headlights have special protections built in. Machine covers are formed steel, and hydraulic hoses are easily accessible for replacement – some have been redesigned to make them even easier to repair in the field. Practical design touches are everywhere: all Brokk machines can rotate 360 continuous degrees, but they can also operate ‘over the back’ and work unencumbered.

SmartRemote

Over forty years of experience in the design of remote-controlled demolition machines have led to leading edge ergonomic remote control boxes. Brokk’s approach uses a wide adjustable belt to hold the remote control box comfortably around the operator’s waist. This places the weight where it belongs, on the hips, and away from the upper back. Intuitive controls allow the operator to work the machine without having to spend time watching the display. The best operators become one with their robots, maneuvering them smoothly and positioning them quickly around the jobsite. Professional grade radio technology, with frequency hopping capability, has exceptional availability and a working range of up to 300 meters. It is quick to connect, resists interference, and is highly reliable.