In the spotlight at FinnMetko 2024

Story Highlights

- John Deere Forestry

- utilaje forestiere John Deere

- forwarder John Deere

- harvester John Deere

- cap de recoltare John Deere

- Elmas - distribuitor autorizat al John Deere Forestry in Romania

- John Deere 1270H

- John Deere 1470H

- John Deere 2010H

- John Deere 2510H

- #yournewstandard

Related Articles

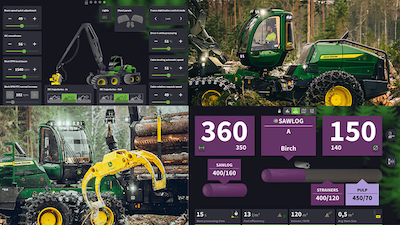

The brightest attractions at John Deere’s exhibition stand are the H Series harvesters 1470H and 1270H as well as the 2010H and 2510H forwarders, released in spring. The new H Series forest machines offer increased productivity, the joy of work, and easy serviceability, and they represent the future of logging with their industry-leading innovations. The new H216 harvester head, which brings increased precision and productivity to large harvesters, will also be showcased at FinnMetko 2024.

Harvesters 1270H and 1470H

Harvesters 1270H and 1470H

The engines of the new H Series harvesters offer 10% more power and torque. New hydraulics with three dedicated pumps deliver more power and increased work pressure for feeding. The optimized system ensures a good fuel economy. The new Active Frame Lock provides enhanced machine stability on steep slopes and flat ground. This makes it easier to work when the boom is positioned sideways, giving the operator a larger working area.

The harvesters’ new H7 and H9 booms deliver approximately 10% more lift power. The slewing torque of the H7 boom has been increased by 10% and the H9 boom by 5% higher compared to previous models. The new design of the H Series harvesters prioritizes operator wellbeing: increased comfort and enhanced visibility. The engine has been turned 180 degrees, the hydraulic oil tank, fuel tank and pumps have been placed in front of the engine, and the radiator and fan are behind the engine. These changes result in a very quiet cabin. The rear of the machine has been lowered, greatly improving rearward visibility.

The rotating and leveling cabin is now standard in the H Series. The cabin turning angle has been increased by 30 degrees in both directions, so the cabin can now turn 220 degrees. John Deere’s collaboration with BMW Design Works is evident in the design.

Forwarders 2010H and 2510H

Forwarders 2010H and 2510H

The new size-class 20-ton and 25-ton forwarders offer 25% more load capacity. The new twin motor driveline in the 2510H forwarder also offers a 50% faster driving speed. The twin motor driveline is also an available option for the 2010H forwarder. The new booms have more power and longer reach. The reach of the F10 boom, the strongest forwarder boom in the market, is 10.2 meters. The F9 boom has a reach of 10.7 meters. The hydraulic hosing and hose routings have been improved. Larger grapple options are now available, thanks to the 40% increased boom lift torque and 22% higher slewing torque. The new F9 boom has 13% more lift torque and 10% more slewing torque than its predecessor.

New boom geometry and five articulated joints between the main boom and jib boom improve controllability and load handling precision as well as maintain a consistent speed throughout the loading cycle. The new H Series forwarders are also available with a boom tilt, which enables a backwards tilt angle of 22 degrees. This significantly facilitates working on steep slopes. The new frame lock increases stability also with a full load. The cylinder-operated frame lock improves stability when transporting large loads over long distances.

John Deere cabins are designed to keep the operator energized the entire work day

John Deere cabins are designed to keep the operator energized the entire work day

H Series cabins are designed to support the wellbeing of harvester and forwarder operators and to promote ease of use. The TimberMatic H control system’s clear and intuitive interface guides the operator to the best possible performance. The redesigned cabin is a response to the wishes of forest machine operators. Sound-insulating materials have been used in the interior, and repositioned fresh air intakes and improved climate control ensure a stable temperature in changing conditions. High-quality lighting solutions improve visibility of the working area.

The redesigned cabin has more storage space as well as many practical features, such as a wireless charging tray for a phone, a space for shoes and a water bottle, and a lunch tray table. Other new features include a secondary display for easy access to machine’s basic functions and cameras, a drive direction selection pedal, a premium audio system with bass and treble speakers, multiple charging outlets, and new hand control panels with configurable buttons, new mini joysticks with configurable buttons, and multiple seat options and seat ventilation.

The new Intelligent Cabin Key is a personalized remote key that unlocks the machine door and provides access to the PC and TimberMatic control system with operator-specific configurations. The Intelligent Cabin Key can also be configured for service personnel and flat trailer operators. The Intelligent Cabin Key includes immobilizer locking.

New John Deere Protect Service Agreements

John Deere Protect is an enhanced service agreement offering for John Deere forestry machines to maximize the reliability, uptime and performance of your equipment. Two maintenance plan options are available, featuring service intervals of either 750 or 1000* hours, as well as many supplementary services, such as extended warranties and performance optimization. A service agreement can be set up for new or used machines.

*1000-hour service intervals available only for H Series machines.

New H216 harvester head for big harvesters

New H216 harvester head for big harvesters

The new two-wheel drive harvester head for hardwood and softwood is designed for large size-class harvesters, and it replaces the previous H270 harvester head. The H216 harvester head is fully compatible with H Series harvesters and track-mounted harvesters. The H216 harvester head options include top saw, long processing knives, HD tilt handle, find end sensor and multispeed feed motors. The saw unit allows the use of wide and long saw bars when handling large trees. The new head is available for 1270H harvesters with an 8.6/10.0-meter boom reach and 1470H harvesters with an 8.6/10/11-meter reach.

IBC 3.0 brings more automatic functions to forwarders

Intelligent Boom Control, IBC, is a technology continuously developed by John Deere to improve the productivity of logging and make the forest machine operator’s job easier. The forwarder’s advanced IBC 3.0 and its automated functions were introduced in 2023. The boom can be moved to the transport position or opened from the transport position to the working position at the push of a button. When working, the empty boom also returns to the loading position at the push of a button. IBC 3.0 is standard equipment on H Series forwarders.

Timbermatic Maps application’s new map layers

Timbermatic Maps application’s new map layers

The new map layers, developed in collaboration with customers, support more accurate preplanning of the logging site. The accessibility map layer now also shows steep slopes and rock outcroppings, and the wet and dry season map layers help with the seasonal variation in logging site planning. The thinning yield estimate provides a preliminary estimate of the volume of vertical trees per tree species.

A more comprehensive service network

John Deere Forestry Oy has expanded its service network in Finland during the past two years by adding two new customer service centers and two spare parts sites. In addition to seven regional customer service centers, a comprehensives service agreement network serves customers in different parts of Finland.

Competitive financing solutions

John Deere also offers a competitive financing package, flexible payment terms, and tailor-made solutions for forest machine companies. Financing is available for forest machines, extended warranties, and accessories in one contract and at a clear total cost of ownership.

Industry-leading solutions and services from a state-of-the-art production system

The H Series forest machines, equipped with John Deere’s digital solutions and lifecycle services, represent the future of logging. The totally new TimberMatic H control system and integrated TimberMatic Maps as well as Deere’s wireless connectivity enable real-time data sharing and global coverage through collaboration with industry-leading service providers. Map-based visualizations and real-time data sharing result in effective site planning, operator assist functionalities, and reporting. The modern software architecture and continuously evolving data integration are the basis for a production system that meets the forest industry’s needs both today and into the future.