New hybrid HiLight BI+ 4 light tower from Atlas Copco improves energy efficiency and operational productivity

Story Highlights

- Atlas Copco

- turn de iluminat hibrid

- Atlas Copco HiLight BI+ 4

- hybrid light tower

Related Articles

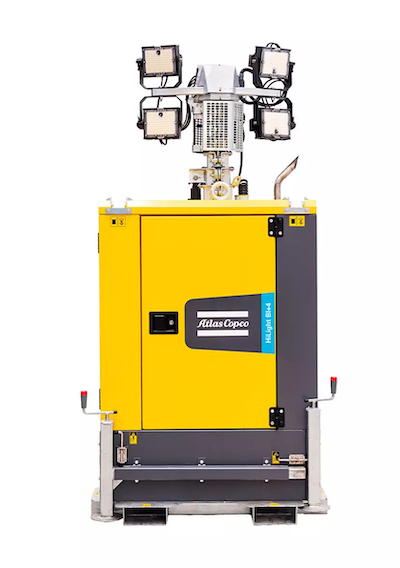

Atlas Copco has launched its first hybrid light tower, the HiLight BI+ 4, which is set to transform industry. The innovative light tower incorporates state-of-the-art surface mount device (SMD) LED lighting technology and lithium-ion batteries to provide excellent performance and efficiency. Operators at construction sites, events, mines, emergency applications and rental companies will be able to reduce their carbon footprint and operating costs while improving sustainability levels – both environmentally and in business.

Combining the use of lithium-ion batteries with a low-consumption Stage V diesel engine, the new HiLight BI+ 4 light tower offers users maximum flexibility as it has four operating modes: it can be powered directly from mains electricity, from its lithium-ion batteries, from its diesel engine, or from a hybrid setting to make the most of the energy available.

The light towers have a battery autonomy of seven hours when operating at their full potential. And, when using their dimming function, they can provide over 20 hours of silent and emission-free operation with a single charge. With a battery recharging time of just four hours, the HiLight BI+ 4 can also feature an external power plug as an option.

When operating in hybrid mode, relying on both the batteries and the engine, the light tower’s fuel consumption is an average of 0,29l/h, which is the lowest average fuel consumption in its class of light towers. Thanks to the incorporation of a battery, operators can reduce up to seven tonnes of CO2 per unit, per year, compared to traditional diesel-powered light towers. By optimizing their energy consumption, users can reduce their environmental impact and improve their profitability considerably.

When operating in hybrid mode, relying on both the batteries and the engine, the light tower’s fuel consumption is an average of 0,29l/h, which is the lowest average fuel consumption in its class of light towers. Thanks to the incorporation of a battery, operators can reduce up to seven tonnes of CO2 per unit, per year, compared to traditional diesel-powered light towers. By optimizing their energy consumption, users can reduce their environmental impact and improve their profitability considerably.

The 5kW lithium-ion battery technology delivers a higher performance than comparative light towers powered by absorbent glass mat (AGM) lead acid batteries. The lifespan of a lithium-ion battery is superior in comparison and is expected to last approximately 36,500 hours, compared to just 1,500 hours for AGM lead acid batteries.

Introducing the ability to use batteries reduces the use of the engine, which extends the unit’s lifetime and results in a temporary lighting solution with a low Total Cost of Ownership (TCO). With a 60% reduction in engine runtime, service intervals are three times longer than light towers that run solely on diesel. The HiLight BI+ 4 requires minimal maintenance every 1,500 hours of lighting, so users can save on costs associated with servicing.

The flexible temporary lighting solution is also the first of Atlas Copco’s light towers to feature highly efficient SMD LED lights, which are 20% more efficient than alternative Chip-on-Board (COB) LED lights found in alternative light towers and competitive solutions. Each light tower has four floodlights providing 150W power to reliably cover 4,000m2, extending the working days and contributing towards a safe working environment. The HiLight BI+ 4 is ergonomic, with fully hydraulic mast lifting and electric mast rotation, which is easily controlled on the system’s control panel.

The box-type light tower is 15% lighter than any hybrid light tower available on the market. Operators can fit up to 22 units on a standard 13-metre Eurotruck, which positively impacts transportability and improves operational efficiency.