Intelligent assistance systems for Liebherr’s XPower large wheel loaders

Related Articles

At bauma 2019 Liebherr presented a comprehensive package of multiple intelligent assistance systems for its XPower large wheel loaders to the audience of construction industry professionals for the first time. These systems include the new active rear person recognition and a sensor-supported, integrated tire pressure monitoring system. With these and other assistance systems, Liebherr is able to offer integrated solutions for optimizing safety and comfort in day-to-day wheel loader operation. All systems have been developed by Liebherr and are therefore fully integrated into the machine control. Another Liebherr wheel loader world première is a new intuitive steering system, available for all mid and large series models after bauma 2019.

Active rear person recognition helps prevent accidents that result in personal injury

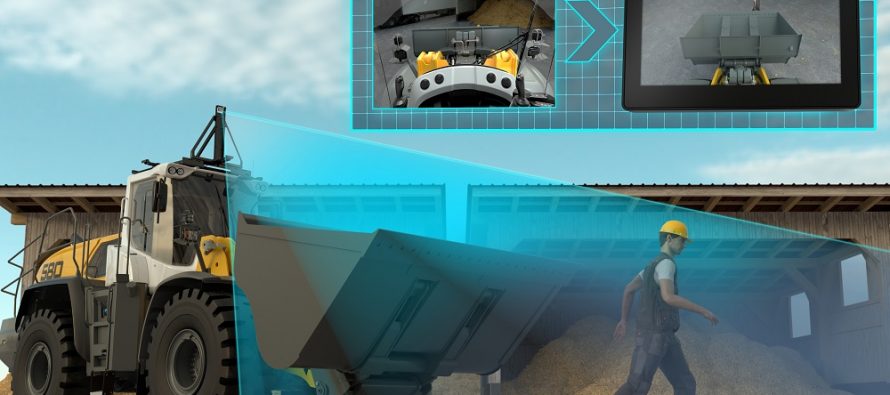

Liebherr’s new assistance systems increase comfort and safety in daily operation in a range of ways. One of their advantages is that they enable machine operators to concentrate more on operating their Liebherr wheel loader by removing additional distractions. For example, the active rear person recognition automatically provides a warning on the machine display and sounds acoustic signals if there is danger in the wheel loader’s rear area. A special feature of this system is that it uses sensors to automatically differentiate between people and objects with the aid of sensors.

If a person moves in the area behind the machine, the system alerts the machine operator. The active rear person recognition is activated at a greater distance than warning systems for inanimate objects such as walls or columns. The operator, therefore, receives a more precise warning if there is a risk of personal injury. The active rear person recognition thereby avoids an overload of warning signals, which in turn reduces the burden on the machine operator. The risk of serious accidents is reduced.

Integrated tire pressure monitoring system increases tire lifetime

Integrated tire pressure monitoring system increases tire lifetime

Tires are among the most expensive wearing parts on a wheel loader. Incorrect tire pressure leads to increased wear and rising fuel consumption and results in high costs. Other negative consequences are stability limitations and reduced maneuverability. It is therefore important to address potential tire pressure problems in good time. Liebherr offers a newly integrated tire pressure monitoring system for this purpose. It detects tire pressure deficiencies early, ensures good maneuverability and increases the lifetime of the tires.

With the aid of sensors, which are installed on the tires and protected from damage, the system records the status of the tires and indicates this on the machine display. If there are deviations from optimal tire pressure, the machine operator receives a warning notification on the display. The operator can, therefore, act early if there is insufficient pressure or excessive temperature levels in order to avoid safety risks and high associated costs. The integrated tire pressure monitoring system is available as standard for many wheeled earthmovers and container handling machines across the Liebherr group of companies.

New stereoloaders are premium machines in the small wheel loader sector

New stereoloaders are premium machines in the small wheel loader sector

For decades, Liebherr’s stereoloaders have been widely recognised as productive premium machines in the small wheel loader sector. With the L 509 Speeder and the L 518 Stereo, Liebherr showcased two representatives of the latest stereoloaders at bauma 2019. Liebherr has recently completely reworked the latest series, which comprises a total of four models from the L 507 Stereo to the L 518 Stereo. All models are available in a Speeder version on request. In this version, stereoloaders can reach a top speed of up to 40 km/h. This helps operators save time and enables them to move their wheel loader from one operation to the next quickly.

The stereo steering developed by Liebherr is unique. It is an ideally balanced combination of articulated steering and rear-axle steering. It, therefore, combines the advantages of conventional articulated steering with the advantages of all-wheel steering. The resulting minimal turning circle is particularly practical when space is limited. The controlled rear-axle enables Liebherr engineers to reduce the articulation angle of stereoloaders to 30 degrees. As a consequence, the center of gravity remains in the center of the machine even when transporting large loads, which increases stability.