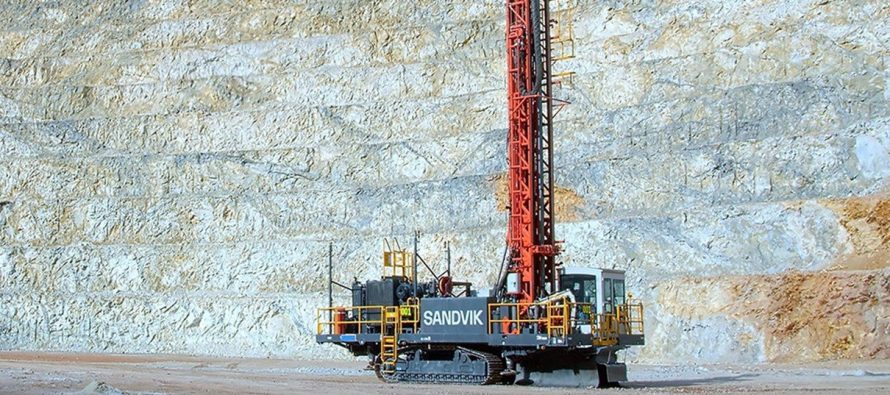

Sandvik adds to its iSeries family of rotary blast hole drills with the DR410i

Related Articles

Continuing its long tradition of developing innovative technology to help its customers enhance safety, improve productivity, and reduce cost, Sandvik Mining and Rock Technology has introduced the Sandvik DR410i rotary blast hole drill.

Compact, powerful and technologically advanced, Sandvik DR410i is designed to deliver unmatched productivity and return on investment for 6-97/8” (152-251 mm) rotary and DTH holes, with a standard mast offering a first pass capability of 10 m and a max depth of 46.6m. The extended mast option delivers a first pass option of 14 meters with a total depth capacity of 32.3m across all recommended pipe diameters.

Compact, powerful and technologically advanced, Sandvik DR410i is designed to deliver unmatched productivity and return on investment for 6-97/8” (152-251 mm) rotary and DTH holes, with a standard mast offering a first pass capability of 10 m and a max depth of 46.6m. The extended mast option delivers a first pass option of 14 meters with a total depth capacity of 32.3m across all recommended pipe diameters.

The Sandvik DR410i is automation-ready when equipped with AutoMine solution module which provides functionality for both on-board and off-board automated needs. This scalable solution, from on-board automation that increases drilling efficiency to full autonomous operation, is designed to meet customer needs both now and in the future.

The Sandvik DR410i is the result of tireless and innovative design efforts focused on safety, productivity, and value. Key features of the Sandvik DR410i work collectively to increase productivity. The Sandvik Intelligent Control System Architecture (SICA) provides the operator with real-time feedback regarding the machine’s performance and health, ensuring quality and consistency hole-to-hole.

Some of the other key productivity-enhancing features include:

– Single-pass depth to14m without the need to add pipe

– Rotary or DTH drilling options

– 258 kN weight on bit

– Onboard automated features such as Auto Drill and Auto Cycle ensure quality and consistency hole-to-hole.

– Auto Mast and Auto Level functions ensure consistent operations and reduce wear on structural weldments.

– Breakout wrench speeds change from one pipe to another.