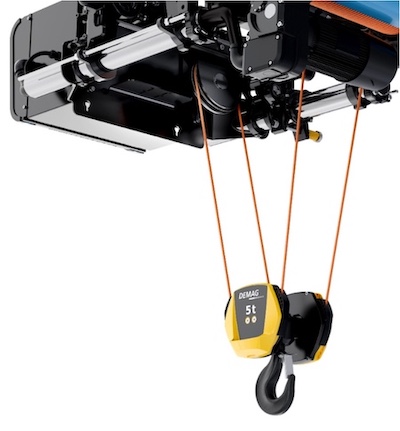

The new Demag DHR rope hoist

Story Highlights

- Demag

- electropalan cu cablu Demag DHR

- ELMAS - Macarale industriale

- DHR rope hoist

Related Articles

Innovative lifting solutions for safe and forward-looking operation: The new Demag DHR rope hoist offers a high level of versatility and productivity. The DHR combines the powerful features of its two predecessor generations: Reliability, productivity and – thanks to numerous options – tailored implementation to meet the requirements of many industries. From simple lifting applications to high-performance rope hoists with smart assistance and convenience features, the DHR meets all demands for highly efficient load handling.

Compact. Innovative. Smart

DHR rope hoists with compact design and low deadweight stand out due to their small external dimensions and a further reduced C dimension. This makes the best possible use of the working space for crane applications or stationary equipment.

DHR rope hoists offer tailored solutions based on a single platform. Additional hardware options and smart features make a DHR rope hoist a smart hoist that is well equipped to meet future requirements: Lifting to the next level.

Demag DHR rope hoists offer smart features that make load handling even safer and more efficient. And transparent at all times thanks to the monitoring and remote monitoring tools.

DHR highlights

DHR rope hoists fulfil almost any requirement:

– EK-DHR: monorail hoist, optimised for use on single-girder cranes or monorails

– G-DHR: basic hoist for plant engineering

With the DHR rope hoist, you have the choice for the first time: Proven lifting technology with steel ropes or with innovative synthetic ropes.

With the DHR rope hoist, you have the choice for the first time: Proven lifting technology with steel ropes or with innovative synthetic ropes.

Features of the synthetic rope:

– Made of high-modulus polyethylene fibres

– 12-strand non-rotating structure

– Around 85% lighter than steel rope

– Suitable for indoor and outdoor use

– Temperature range: -10°C – +45°C

– No lubrication required

– No wear on rope drum and return sheaves

– One type of rope for all applications

Smart features

– Load-sway reduction. Prevents increased load sway by active counter-movements of the crane. Active system based on rope angle measurement.

– Slack rope protection. Continuous monitoring of rope tension: Automatic cut-off of the hoist motor when slack rope is detected.

– Area-dependent load reduction. Defined areas that the trolley may only enter when the load does not exceed a reference value.

– By-pass control. Defined restricted areas (e.g. structures, machines) that must not be approached by the trolley.

– Tandem control. Loads can be transported safely with two DHR rope hoists – all from a single control unit.

– Follow-me. Crane can be moved over the load by simply guiding the hook by hand. (Recommended for cranes up to 10 t).

Hook centring

Hook centring

Automatically positions the crane hook directly above the load. The advantages: faster load cycles and improved ease of operation.

Diagonal pull prevention

Rope angle monitoring, automatic cut-off in the event of diagonal pull (> 4°) to avoid dangerous situations.

Full control – from anywhere: Demag StatusControl 2.0

With Demag StatusControl 2.0, smart system management, you have full control of your rope hoist at all times and from anywhere. Our remote monitoring system provides you with up-to-date operating data and evaluations for the DHR – as a solo component as well as in crane applications. Full transparency on utilisation, usage, risk of downtimes and service life.

Real-time operating data: Demag Equipment App (DEA)

Do you only find out the usage and wear data for your DHR rope hoist once a year during inspection and maintenance? This is a thing of the past with the Demag Equipment App. Within the radio range of the hoist, you receive the current data in real time and visually displayed on your end device. Trained users can also adjust DHR parameters.