KLEMM presents its newly developed universal drilling rig KR 606-3

Related Articles

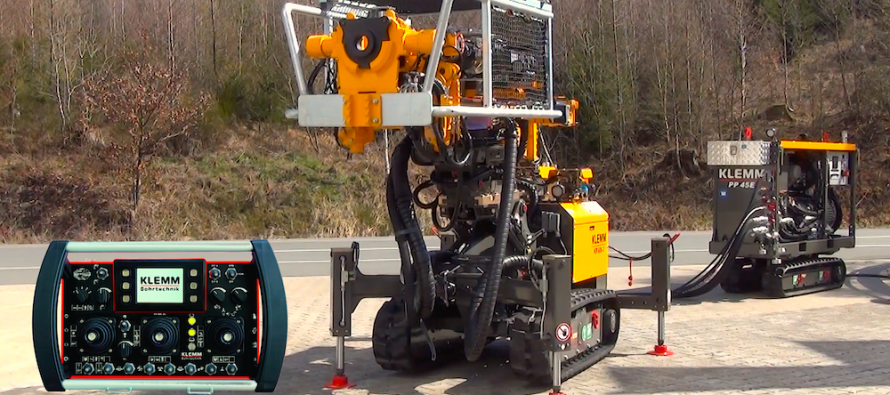

Compact dimensions, low weight and highly variable kinematics – KLEMM Bohrtechnik presents its newly developed universal drilling rig KR 606-3, predestined for extreme drilling positions in especially confined spaces. Due to the modular drilling rig concept, a wide spectrum of applications can be covered: underpinning, jet grouting, micro-piling, soil nailing, and anchoring are all possible with what is currently the smallest and lightest KLEMM drilling rig available.

The newly developed drill rig kinematics allow the boom to rotate around the vertical axis of the drill rig. Other important features include the telescopic function of the height-adjustable boom, and the tilt and rotation function of the mast carrier, which, among other things, enables drilling positions to be set up conveniently alongside the crawler tracks. Four outriggers support the drilling rig, which, along with the asymmetrically telescopic chassis, ensure a high degree of stability.

The newly developed drill rig kinematics allow the boom to rotate around the vertical axis of the drill rig. Other important features include the telescopic function of the height-adjustable boom, and the tilt and rotation function of the mast carrier, which, among other things, enables drilling positions to be set up conveniently alongside the crawler tracks. Four outriggers support the drilling rig, which, along with the asymmetrically telescopic chassis, ensure a high degree of stability.

With its compact dimensions, the rig is predestined for use within buildings and other construction works. Using the proven remote control unit with display, the operator is always able to assume a safe working position close to the drilling rig.

In accordance with the requirements of EN 16228, operator safety is ensured by the high, functional safety of the control concept. A separating safety guard for moving parts during the work process is available.

The modular mast system includes the 140/3 type mast with gear feed and 30 kN retraction force, and the 120 type mast with cylinder feed and 24 kN retraction force in graduated frame lengths. The 140/3 type mast is also available in a sectional version.

Even greater flexibility is achieved through the newly developed modular system of the PP 45E and PP 55G Power Packs. Like the drilling rig itself, both Power Packs are very narrow, allowing them to pass through confined spaces. The Power Packs are available either on wheeled chassis for towing, on rubber-tracked crawlers, or without chassis as a stationary unit.

Even greater flexibility is achieved through the newly developed modular system of the PP 45E and PP 55G Power Packs. Like the drilling rig itself, both Power Packs are very narrow, allowing them to pass through confined spaces. The Power Packs are available either on wheeled chassis for towing, on rubber-tracked crawlers, or without chassis as a stationary unit.

The Power Pack PP 45E is powered by a three-phase motor with 45 kW output, while the Power Pack PP 55G has a diesel engine with an output of 55 kW. The diesel engine complies with emissions regulations EU stage V and a version complying with emissions regulations EU stage IIIB is also available.

The hydraulic system features include a load-sensing pump and CAN bus-controlled control blocks with high precision controllability and reproducibility. Drilling operations using light hydraulic hammers can be carried out without incurring any problems.